What does it take to remain competitive in the constantly changing world of the manufacturing industry? There may not be a single answer, but one thing is certain: without the right tools and systems in place, it’s nearly impossible for companies to keep pace. For this reason, leading innovators in production are turning to NetSuite’s manufacturing ERP as the solution of choice to run their entire business.

Why Manufacturers Choose NetSuite for Manufacturing

The vast majority (82%) of manufacturers think digital technologies have the potential of fundamentally changing the way we do business, and 86% believe they are necessary for survival.

But why? Manufacturers have been collecting massive volumes of data (ie: sensors on the shop floor) for decades. But that data has largely gone underutilized and has had little connection to the traditional Enterprise Resource Planning (ERP) systems used to run the business. While most organizations rely on data from ERP solutions to make strategic business decisions, most of these systems have been completely disconnected from the vast pools of data available, not only from those sensors, but more recently from smart products and other external sources. However, today we live in a digital world; and with that comes the ability to connect devices, and more importantly, business processes and data, so organizations can make faster and better decisions.

Whether you are making day to day tactical decisions on the shop floor, or strategic decisions on the top floor, organizations need ERP manufacturing software to stay one step ahead of the competition, especially in the production industry.

Who Needs NetSuite ERP for Manufacturer

It doesn’t matter whether a company is a 50-year-old discrete manufacturer running the same on-premise ERP system they have been using since the 90’s, or a high-tech manufacturing startup rapidly outgrowing QuickBooks and Excel spreadsheets. The reality is that these manufacturers—as different as they may appear at face value—are operating in the same business ecosystem and face the same modern day business challenges.

Regardless of the size or age of a company, manufacturers striving for success need an ERP software system that can keep pace, is scalable, and can address the challenges of today.

That is where NetSuite for Manufacturing comes in. Across the NetSuite customer base, there are thousands of manufacturers that fall across the spectrum of size and age; this is because NetSuite revolves its business strategy around five pillars to address the challenges all modern businesses face. These pillars include NetSuite’s:

- Reliable platform

- Industry-specific capabilities

- Global functionality

- Customer experience focus

- Flexibility to accommodate complex business needs

The Benefits of NetSuite’s Manufacturing Software

At its very core, NetSuite’s ERP manufacturing software is designed for the modern business. This fact, combined with years of industry best practices, has made NetSuite both the product provider of choice and a trusted advisor for manufacturers looking for an ERP solution. Based on these pillars, let’s explore how NetSuite addresses the needs of a manufacturer going through the ERP selection process.

Whether a manufacturer is in its first round of seed funding or its 50th year of business, it is critical that manufacturers are equipped with the manufacturing-specific functionality to increase efficiencies, improve utilization and reduce errors. With more than 30 years of experience in ERP, NetSuite has developed industry-specific functionality to address these exact manufacturing-specific needs. From order capture and inventory management to shipment and billing and support, NetSuite manages the entire manufacturing process flow. It supports inventory for multiple locations, assembly management requirements, bill of materials management, work order management, diverse methods of measurement and bar coding.

NetSuite’s Advanced Manufacturing Software Does It All

On top of the core functionality, NetSuite ERP offers an Advanced Manufacturing edition, which caters to even more complex manufacturing requirements, including:

- Manufacturing Execution Systems

- Bar Code Scanning

- Tablet Experience

- Advanced Routings

- Rough Cut Capacity Planning

- Resource Requirements Planning

- Quality Control

- Batch Control & Management

- Recipe/Formula Management

- Dynamic Reporting

- Release Management

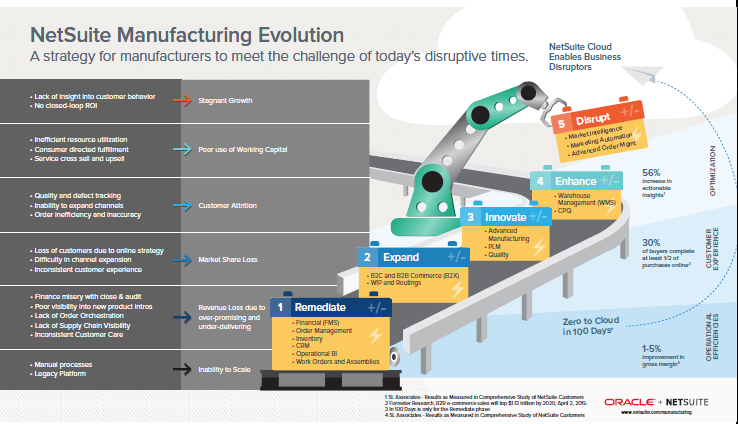

As critical as the functionality of ERP manufacturing software is, many businesses are understandably concerned about the agile implementation process. With decades of experience in ERP implementations, NetSuite has developed manufacturing-centric “stairways” that walk businesses through a stepped approach to adopting functionality that helps to implement NetSuite’s manufacturing capabilities at a comfortable pace.

Hear It From the NetSuite Customer

CraftMark Bakery aims to change the game in baking by offering high quality products, with extreme

agility and rapid time to market. For this reason, during its ERP selection process, CraftMark Bakery sought manufacturing best practices and the deep functionality that could match its detailed requirements and aggressive schedule. The company needed a cloud-based solution that could support its expansion and rapidly scaling business.

NetSuite delivered exactly the platform that CraftMark Bakery was looking for. It provides an agile platform, manufacturing best practices and a user-friendly interface. CraftMark uses NetSuite for manufacturing across all of its operations—from procurement and inventory management to distribution and financial reporting—and even utilizes NetSuite’s mobile capabilities on its shop floor.

The NetSuite ERP is Built to Last

Of course, companies exploring their ERP manufacturing software options also want a solution to last well into the future, and can scale as they grow. Big or small, replacing a company’s systems is no easy task, which is why reliability and sturdiness of the solution are absolutely critical. The last thing a business wants is to go through the process of selecting an ERP just to have to implement additional painful upgrades or even get another ERP consultation.

NetSuite for manufacturing is the kind of solution that is built to last. It is global, accessible at any time from any device, and automatically updates with the latest features and functions so that customers are always running the latest version. It is able to handle a broad range of business needs—from small companies with a handful of employees to huge global enterprises—and it’s highly customizable, with a massive ecosystem of partners with built-for-NetSuite offerings.

NetSuite ERP has consistently focused on enhancing the performance of the platform, for startups and large enterprises alike. This fact, combined with NetSuite’s customizable cloud-based architecture, makes NetSuite for manufacturing the solution of choice for companies seeking a proven system along with all of the key updates and functions.

Hear It From the NetSuite Customer

CMP, the world’s largest independent manufacturer of aftermarket compressor parts for refrigeration and HVAC units, runs NetSuite ERP as a core component of a lean manufacturing initiative, aimed at eliminating waste. With lean manufacturing, CMP Corp. has systematically transformed its business for greater cost-efficiencies across core business processes in both aftermarket and custom-machined lines of business.

NetSuite Advanced Manufacturing Edition enables CMP to streamline production with such capabilities as work orders, bills of material, assembly management and requirements planning, while NetSuite’s cloud infrastructure enabled CMP to reduce its server count from 10 to two while trimming its IT staff by one full-time employee and eliminating reliance on third-party IT consultants. Avoiding high capital expenses for a new ERP solution enabled CMP to focus its resources on devising and implementing its highly successful lean manufacturing program.

https://www.withum.com/resources/transforming-todays-manufacturer/

NetSuite for Manufacturers Streamlines Global Production

It is no secret that global functionality has rapidly become a vital aspect of success in the modern business world. With many manufacturers moving production or warehousing overseas and selling into international markets, global functionality is a critical piece of the puzzle for many in their ERP selection. Large companies require agility to take advantage of global opportunities while small companies are operating internationally and need a solution that allows them to do so. NetSuite provides a global solution that moves at the speed of business and provides small and large companies alike with the functionality needed for success.

When choosing an ERP solution, another factor manufacturers consider are the challenges associated with managing complex, international supply chains. With companies focusing more on partnering and outsourcing for increased efficiencies, supply chains are becoming more fractured and international.

NetSuite’s manufacturingERP meets this need for a global infrastructure to accommodate more fractured supply chains, international fiscal functionality, multi-level company structures and global supply chain functionality through:

- Scalable Infrastructure: New data centers around the world brings NetSuite’s solutions closer to customers, ensures data protection and makes it easy for customers to add subsidiaries, sales offices, distribution centers, manufacturing plants, contract manufacturers or business partners.

- International Fiscal Functionality: NetSuite for manufacturing provides the fiscal capabilities to easily support companies in any country, supporting more than 20 languages, 190 currencies and financial compliance laws across more than 110 countries worldwide—and makes the process of going global more streamlined.

- Multi-Level Company Structures: NetSuite natively provides the ability to accommodate multi-level company structures to seamlessly account for parent and subsidiary corporations. Some companies—including Shaw Floors—take a two-tier ERP approach, in which a subsidiary runs on NetSuite, enabling the parent company to leverage the on-premise system it has already invested in heavily.

- Global Supply Chain Functionality: With NetSuite ERP, businesses are able to optimize global supply chains by planning the supply chain, managing available capacity, optimizing inventory and executing on the supply chain with visibility into every portion of it.

Hear It From the NetSuite Customer

Akustica, Epec and Shaw are all businesses operating globally and have chosen NetSuite for manufacturing to fully manage their supply chains. Benefits these successful companies have experienced in turning to NetSuite include:

• Real-time updates of information and visibility across their company and supply chain.

• Integration with other systems for complete visibility from raw material purchasing and manufacturing, to fulfilling orders and billing.

• More automated operational processes.

• Easy-to-use dashboards.

• Ability to expand and grow globally due to ease of scalability.

• Access from any location from any device.

• Multi-language and multi-currency capabilities.

ERP Systems Greatly Improve Customer Experience

As manufacturers expand more and more into B2B and B2C commerce, the customer experience becomes a key consideration. In the modern world of business, there are more touch points with the consumer than ever before. Customers expect consistent experiences regardless of how they engage—whether via the web, call center, mobile device or otherwise.

Modern manufacturers need the capacity to communicate with their stakeholders and customers effectively and seamlessly, a key advantage of the NetSuite ERP commerce solution. NetSuite’s SuiteCommerce engine:

- Enables implementation of both B2B and B2C portals that streamline order placement and improve customer satisfaction.

- Streamlines order management by transferring orders automatically to back-office fulfillment processes.

- Automatically creates dynamic price lists that reflect purchase volumes.

- Supports creation of coupons or discounts on specific items, enables exempting other items from discounts and automatically delivers upsell recommendations.

- Provides search engine analysis, website analytics and reporting, online marketing analytics and more.

- Accepts real-time payments from different credit cards and international currencies and supports Google Checkout or PayPal checkout options.

Between multi-channel purchasing support, quote request, password protection, application performance sensors and Google tag manager, SuiteCommerce optimizes the online ordering process from start to finish. These capabilities are the core of the customer experience and absolutely necessary for the most optimized B2B and B2C commerce possible.

How to Get Started With ERP Manufacturing Software

In the face of constant change, businesses need to quickly be able to pivot and iterate on their business model, and they need an ERP solution that is going to be able to form to that model. New companies lacking a platform to support and monetize their state of the art innovations and unique business models are at a serious disadvantage as they try to establish themselves in the market, while older companies risk stagnating and ultimately failing if they fail to recognize the need to modernize. For instance, today a company may bill in more traditional ways, but in the future their billing practices may become more complex and they need to be prepared for that potential. Functionality and a flexible platform makes rapid changes in processes possible so that businesses can focus more on innovating and less on the software to support these innovations.

If you’re looking for general ERP consulting help, or want information on how NetSuite for manufacturing can benefit your business, please contact us by filling out the form below.

How Can We Help?