The Digital Connection of Devices, Processes, Data and Decisions

We live in a digital world. Digital communication and digital systems of record are becoming the norm. But “digital” brings far more value than simply the potential of a paperless environment. It also gives us more and better data. But the greatest value of “digital” is in its ability to connect devices, processes and data to faster and better decision making. Whether you are making day to day tactical decisions on the shop floor or in the front office, or strategic decisions on the top floor, you need that connectivity to stay one step ahead of the competition, especially in the manufacturing industry.

The Internet has brought us into the digital age and fueled the digital economy. It has leveled the playing field globally. Even small to midsize companies can establish a global presence, disrupt markets and seize unprecedented opportunity. But be careful what you wish for, because the systems and technology that got you where you are today are unlikely to get you where you need to go. Disruption can destroy markets, but can also create entirely new markets. Unless you are a truly connected manufacturer you are unlikely to be the disruptor and more likely to be disrupted.

The vast majority (82%) of manufacturers think digital technologies have the potential of fundamentally changing the way we do business and 86% believe they are necessary for survival. While 85% agree that digital technologies are truly transformative in the way they connect operations to systems such as Enterprise Resource Planning (ERP), most still struggle to be truly connected.

How connected are you in our digital economy today?

The Digital Age

The Internet has brought us into the digital age and created the digital economy. It has leveled the playing field globally. Even if you are a small to midsize company you can establish a global presence and seize the unprecedented opportunity created by new middle classes in emerging economies. The bad news: So can everyone else. So your next new competitors can spring up from places where, in the past, you would least likely expect them. You will be vying for business amongst stiff competition looking for new and better ways to grow.

Digital Bring Data

The digital age has also brought us access to an unprecedented volume of data. The volume of transactional data stored in enterprise applications like Enterprise Resource Planning (ERP) solutions has presented a challenge to manufacturers for decades. Historical data should be useful in driving tactical and strategic decisions, but in the past it has been much easier to get data in than to get data and decisions out. But the volume of data in ERP pales in comparison to the data available through the Internet in general and the Internet of Things (IoT) in particular.

Digital Brings IoT

Through the Internet of Things (IoT), huge volumes of data can be collected from physical devices, including equipment, vehicles, buildings and other items embedded with sensors, software and electronics used to expose the exchange data.

While the Internet of Things (IoT) has caused a huge stir in other industries, it has been met with less excitement in manufacturing. Many feel it is nothing new. Manufacturers have been collecting massive volumes of data (sensors on the shop floor) for decades. But for decades that data has gone largely underutilized and has had little connection to ERP systems used to run the business. While we rely on data from ERP to make strategic business decisions, most of these systems have been completely disconnected from the vast pools of data available, not only from those sensors on the shop floor, but more recently, from the smart products and other external sources.

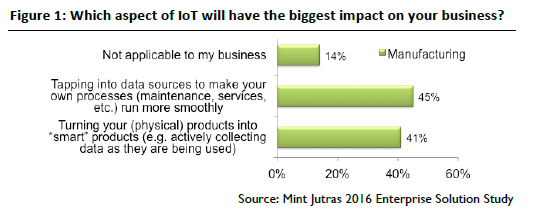

We asked survey respondents to our 2016 Mint Jutras Enterprise Solution Study which aspects of the Internet of Things (IoT) has the potential for the biggest impact on their businesses (Figure 1).

While the IoT may not have caused a big stir in manufacturing, 86% see the applicability of it to their businesses. They are almost evenly divided between seeing the most value from collecting data from “smart” products and tapping into the more traditional process-related data. We expect to see relative importance vary across industry and product types. Products with embedded electronics are more easily made “smart,” and the more automated your manufacturing processes, the more data you can access to control them.

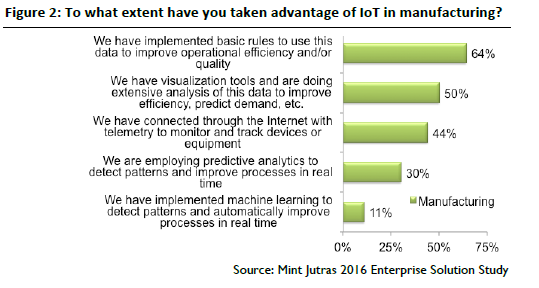

But are manufacturers effectively utilizing this data? We also asked those that see applicability to check off all the different ways they are tapping into the IoT (Figure 2).

The most prevalent use of data mode available through the IoT is in applying basic rules to improve efficiencies and/or quality. This is not much different form how sensors have traditionally been used – to measure and monitor characteristics such as temperature, viscosity, gas pressure and composition – in order to prevent the production of product that is out of specification. Early on, this still required manual intervention, with technicians actively monitoring readings. But over time, more automation was introduced and now basic rules can often be applied through programming of the sensors themselves. However, without connectivity back to the enterprise applications used to monitor and manage the business, the best you can do it shut a process down and send the business into fire-fighting mode. With little or not connectivity how long before you realize your plan has been sabotaged?

Of course by definition this (IoT) data is available through the Internet, making connectivity possible. Connecting equipment, devices and products to the internet is the first step. Figure 2 implies many manufacturers have taken those first steps, but fewer have completed the connection back to connect with enterprise data in solutions (like ERP) to aid in visualization, analytics and machine learning. This is what is needed to provide a complete picture and make proactive, predictive and strategic decisions.

But connecting the IoT back to the enterprise applications that run the business to improve efficiencies is just the beginning.

Connecting to Additional Revenue

Think about how connecting to devices and/or equipment can lead to new sources of revenue or even entirely new business models. If you sell equipment that must be serviced in the field, does that connectivity allow you to monitor how and how much it is used? Perhaps your customer already contracts with you to maintain and service this equipment. Can connectivity help you anticipate service parts and repairs, helping you reduce costs and improve service? Can you charge a premium for additional proactive and prescriptive services?

Is there a “consumable” associated with the equipment like film, inks or toners, or perhaps parts that must be routinely replaced like filters, belts and batteries? Could you automate the replenishment through remote monitoring? What additional services could you offer through the use of data collected form smart products?

If you, the manufacturer can take ownership of this remote monitoring, perhaps your customers would like you to retain complete ownership and simply subscribe to your services. While an oversimplification, this is the classic rent versus buy decision. Subscribing to your services relieves them of an up front capital purchase and the cost and risk of obsolescence. And it provides you with recurring revenue and invaluable data on how your products are used and how well they perform.

Manufacturer of large, capital equipment aren’t the only kind of manufacturer that can find new courses of revenue from connectivity. Think about the possibility of connecting office equipment like printers or residential equipment like water filters. These are lower priced (not capital) items and you potentially get more revenue form the aftermarket sale of inks and toners or water filters than you do from the up front sale of the product… that is, unless your customer finds a cheaper source for those consumables.

So maybe instead, you give those products away and sell a service and subscription to the consumables. And if those devices are smart devices connected back to you, you know exactly when and how much to shit and you can personalize the service. The customer is well-serviced and happy, but more importantly, a customer for the life of the product. And at end of life, you can proactively upgrade or replace it.

Of course this doesn’t apply equally to all kinds of manufactured products. It may be hard to make food and beverage “smart products.” But even with consumable consumer products, who knows what might happen with smart packaging that could someday automate replenishment? Far fetched? There are a lot of examples today that would have been called far fetched a short few years ago.

Disrupt or be disrupted

It is indeed this type of connectivity, in combination with digital transformation, that increases the risk all companies face today in terms of the potential for disruption. We need to be ready for a future that is unpredictable at best.

Think about how industries were disrupted in the past. Think how digital photography impacted giants like Kodak and how personal computers contributed heavily to the demise of (previous) market leaders like Digital Equipment Corporation (DEC). Neither of these sample companies were prescient enough or nimble enough to transform themselves into what would prove to be the next generation of leaders in their respective fields.

But this (risk of new, innovative products) isn’t the only risk faced today. Some threat comes from entirely new business models. Uber totally disrupted the taxi industry. The new business model behind Netflix put Blockbuster stores out of business. Neither saw these new business models coming. What if it happened to you? Would you have the intellectual agility to see it as a threat? Would you have the technology in place to help you make the necessary business transformation to weather the storm? Or would your lack of connectivity be the final nail in your coffin?

You don’t have to come up with the next Apple Watch or be the genius that thinks up the next Uber to be a disruptor yourself. All you have to do is think about growing your business in other ways beyond making and shipping more product. If your products are connected, the possibilities just might be plentiful.

If for example you make and ship any type of industrial or medical equipment, large or small, think about putting sensors on or in the devices, connecting them to the cloud, and monitoring usage. Ask yourself these questions:

- Can you use this data to improve machine productivity and reliability?

- If this is large equipment, would your customers benefit from turning a capital purchase into an operating expense? If so, don’t sell it to them, but instead install it at their site and charge them a recurring fee (subscription) to maintain it, and perhaps even operate it (charging for services). They are relieved of the burden of maintaining the equipment and you insure it is kept in top condition until it is time for an upgrade or replacement. And when the time comes, there is lower risk of them running obsolete equipment because of lack of budget. Furthermore, a (recurring) subscription is a more stable and predictable source of revenue for you.

- Is the after market sale of consumable products or replacement parts a source of revenue? Would connecting these devices give you more reliable and predictable sales, perhaps with less or no human interaction? If you know water filters need to be replaced after processing a certain volume of water, the connected device can automatically order a replacement. If you know historically how many gallons are processed per week or per month, you can anticipate the order and have it readily available in stock, just in time. If you connect this directly back to your ERP solution, you can manage all of this by exception, with little or no human effort, freeing up your people for less mundane and more valuable tasks.

- Would you benefit from monitoring how these devices are used? Could you provide valuable feedback to your design and engineering staff while also personalizing your customer engagement?

While most of these ideas are simple variations on the business models you currently use, these ideas might just lead to entirely new business models. Uber, Netflix and Airbnb didn’t create new products or industries. But they certainly operate under entirely new Internet-based business models.

Because most of the examples we hear about today are consumer-based, the tendency might be to ignore the impact on other enterprise and industrial sectors. But even mature industrial companies like General Electric are exploring ways of tapping into the IoT of new business models. Its new energy business (called Current) is a good example. Instead of selling a customer a single LED light, the goal is now to sell lighting, not just as a service, but as a package of energy-related tools that a customer can use to reduce power demands.

As the digital age brings the risk of disruption, the bottom line is this: If you aren’t seeking out new or varied business models, you are a sitting duck for those that are.

Be Careful what you wish for

While all these possibilities signal unprecedented opportunity, once you enter this brave new world, everything changes. While making and shipping product has never been simple, with new pricing and billing models, or even completely new business models, it is going to get a lot more complex.

Think about invoicing – a relatively straightforward process when you build and ship a product. When you combine subscription pricing, consumption and/or services, it is not so simple anymore. Does your current system allow you to combine product sales, service and recurring fees all on a single invoice?

Combining all of these makes cash flow projections and revenue recognition more complex. In fact in mixing new recurring revenue and adding more services, you are likely to be subject to looming changes in revenue recognition rules as a result of the convergence of ASC 606 and IFRS 15.

While these revenue recognition changes don’t go into effect until the start of 2018, they will have a significant impact on your revenue forecasts and perhaps even your operations. Does your current solution handle them? If not, will it in time? If not, you need to be considering a replacement now in order to give yourself time to implement and prepare.

While fit and functionality has always topped the list of selection criteria for solutions that run your business, there is danger in complacency, believing the solution you choose (or chose) always will meet those needs without changing. If you do need to replace your current solution, there is even more danger in making a selection solely on your requirements today. You don’t want your enterprise applications like ERP to be the reason you can’t take advantage of new opportunities. Windows of opportunity open and close very quickly today. Agility becomes just as important as functionality – if not more so.

Digital Preparedness

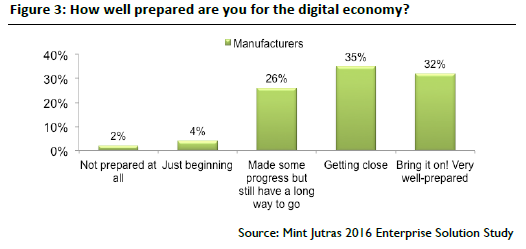

So how well connected are manufacturers today? Digital preparedness is critical to connectivity. We asked our survey participants a similar question: How well prepared are you for the digital economy (Figure 3)? Very few admit to being in very early stages, or not prepared at all, while 26% have made some progress but still have a long way to go. How long is “a long way” and are the 67% that say they are ”getting close” or already there really as well prepared as they might think? We think not.

Our 2016 Mint Jutras Enterprise Solution Study looked at digital transformation from two angles: the extent your transactional system of record is digital and the extent to which activities are performed and/or managed digitally. The scale we use for each of these differs slightly.

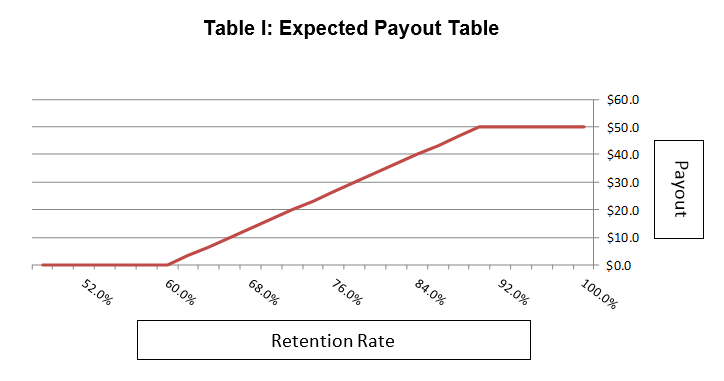

A digital system of record is a prerequisite for connecting digitally with your supplies and customers. In terms of transactions, Table 1 shows our survey participants ran the gamut from completely paper-based and manual (i.e. definitely not digital and not connected) to completely digital, where manual intervention was only required for (digital) approvals and exception handling. One step down from the fully connected, we found a complete digital system of record (e.g. all transactions captured in an ERP solution), but manual data entry was required to capture this data. You settle for people to machine connectivity instead of machine to machine connectivity. Another step down from there was a combination of paper and digital records.

If you compare the percentages in the leftmost column of numbers in Table 1 (the average of this column is 14%) to the 32% that say “Bring it on!” we question the reliability of self-assessment of preparedness. You would also expect the 35% that way they were “getting close” to at least be in the second (from the left) column. The average of that column is only 26%, so that 35% is not very believable either and implies a percentage of those saying they are close still rely at least partially on paper. Which means they aren’t transacting digitally. They aren’t really “connected.”

But it is when we look at the second aspect – the activities that can be performed and managed digitally (Table 2) – where the credibility around preparedness starts to really fall off.

Not only do we see a relatively high percentage of “paper and manual” in this table, but we are very concerned over the continued reliance on spreadsheets. Of course some use of spreadsheets is simply the result of familiarity and comfort level. But that doesn’t make it any less troublesome.

Do you really think you can survive in the digital economy if you are still dependent on spreadsheets? How can you truly connect?

Cloud is a necessary component

So where and how d you connect? Given the Internet has enabled the digital economy, it only makes sense that the cloud is a logical place to connect. Cloud refers to access to computing, software and storage of data over a network – generally the Internet.

As we noted earlier, the Internet levels the playing field, allowing companies of any size to compete on a global basis. Cloud-based solutions in general and those delivered as software as a service (SaaS) in particular, can be the great enabler of global growth. No capital expenditure required; no need to build out a data center, or even put hardware or a huge information technology (IT) staff in country. The access any time, from anywhere nature of a cloud solution is conducive to supporting distributed users and bringing up remote sites rapidly and easily. While cybersecurity is an understandable concern to all today, SaaS solution providers not only deliver added security, but also the peace of mind of business continuity in the event of a disaster, either natural or man-made.

But more importantly, the Internet serves as a gateway for manufacturers to connect directly to devices, customers and suppliers. The Internet enables remote access and interoperability without needing to build direct connections to each and every possible source of data and interaction. But there is little value if there are few participants operating in the cloud. If this were (still) the case, who would you connect to? Fortunately there is steady movement to the cloud.

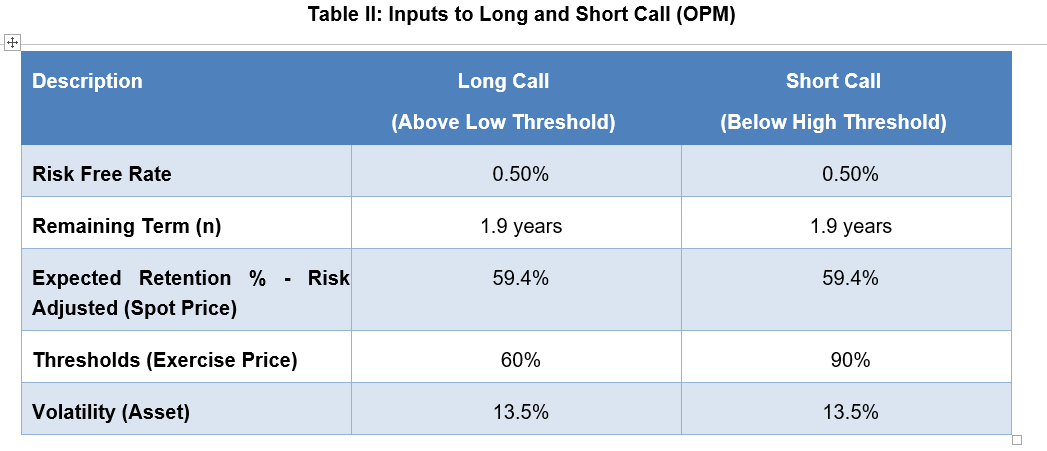

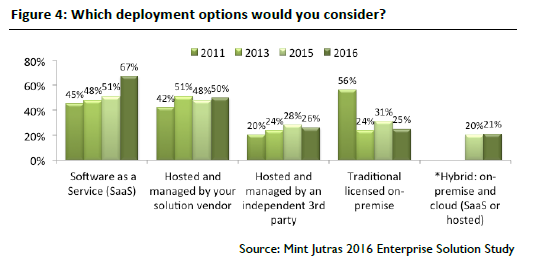

Mint Jutras has been following sentiments and preferences for traditional deployments versus cloud and Software as a Service (SaaS) for many years. The shift towards cloud started very slowly. Ten years ago we described ERP as the last bastion of resistance of SaaS. Those days are long gone. Figure 4 shows that progression of preference over the past several years. The question posed to survey respondents was this: If you were to select a solution today, which deployment options would you consider? Respondents are allowed to select all that apply. Because this is a hypothetical question, not limited to those conducting a search, we get a very broad perspective.

We’re past the tipping point…SaaS is now the top choice for manufacturers. The cloud has become the place to connect.

Summary

The digital age has arrived, and there is no going back. This new age brings a whole new world of opportunity, but with that opportunity comes new challenges. Among those challenges is the challenge to connect:

- Connect to old sources of data: Manufacturers may have been collecting massive volumes of data from sensors on the shop floor for decades now, but have they truly connected that data to the decisions that guide the business?

- Connect to new sources of data: Can you make your products “smarter?” Can you equip them with sensors, connect them to the cloud and monitor usage?

- Connect with your enterprise applications: By sending this data directly to applications like ERP, you can automate processes and free up people for more value-add tasks. This type of connection is enabled by digital technologies, which most manufacturers acknowledge as necessary for survival. Legacy solutions will be hard to connect.

- Connect to new sources of revenue: Think about how connecting to devices in the field can lead to new sources of revenue by improving or selling more services or automating the replenishment of consumables.

- Connect to your customers: Can you collect data on how well and how much your customers are using your engagement with them? Can you use that data to personalize your engagement with them? Can you use it to provide feedback to design, engineering and manufacturing to improve your product?

- Connect with reality: Don’t overestimate your digital preparedness. Eighty-six percent of manufacturers believe digital technologies are necessary for survival, but many fail to take steps to update or replace outdated technologies in place. Continuing to rely on spreadsheets and/or manual processes will create barriers to connecting to all these other places and things.

The Internet has leveled the playing field globally. Any company, large or small, new or established, can potentially disrupt existing markets or create entirely new ones, not just with new, innovative products, but also from new or different business models. The most successful manufacturers have learned to expect the unexpected. They have learned how to be agile. They have learned how to be connected.

Ask Our Experts

Contact us online, or reach out to a member of Withum’s Cloud Solutions and Management Consulting Services team at [email protected] for further questions or assistance.

|

Walter Merkas, Cloud Technologies Leader T (646) 604 4193 [email protected] |

The information contained herein is not necessarily all inclusive, does not constitute legal or any other advice, and should not be relied upon without first consulting with appropriate qualified professionals for your individual facts and circumstances.

Disclaimer: NetSuite and the NetSuite logo are service marks of NetSuite Inc. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership relationship between NetSuite and any other company.