Using ERP Software to Deliver KPIs to Manufacturing Companies

Many firms in the production industry – especially those in the manufacturing sector – have achieved more efficient business operations by investing in a cloud-based, agile ERP system. Historically,manufacturing companies have been known to be “old-school” businesses — the polar opposite of high-tech software and services firms. In reality, most manufacturing operations are among the most sophisticated users of advanced IT solutions and process software. The majority of factory floors are highly automated and precisely monitored, and they are fed by supply chains and inventories that must be coordinated and optimized. Once produced, manufactured goods must be shipped and tracked through often-complex distribution and retail networks, and a product’s quality must be measured and ensured from its creation on the factory floor to its performance at the end customer.

Given the breadth and diversity of their operations, manufacturers must be able to identify and measure key performance indicators (KPIs) for everything from their financial operations to their factory-floor and shipping efficiencies. By doing so, they create a baseline from which to improve and track their critical processes and to achieve higher levels of business effectiveness and success. ERP platforms like NetSuite give organizations a visual view into important KPIs for manufacturing procedures to support actionable decision making.

Manufacturing Metrics Dashboards Help Alleviate Operational and Supply-Chain Challenges

The manufacturing industry is among the most complex and challenging of all industry sectors given its blend of physical and IT assets, the scope of operations it encompasses – from supplier sourcing through product delivery – and the range of expertise manufacturing employees must possess.

Operations Challenges

- Financial – Manufacturers must track standard financial metrics as well as everything from the cost of materials to the value streams of individual production units.

- Reporting – Workers ranging from the finance team to factory-floor supervisors and works need accurate and, often, real-time reports spanning the full range of relevant operations.

Supply Chain Challenges

- Sourcing – Manufacturers must track parts and materials availability, costs and quality from both primary and secondary suppliers.

- Factory – Manufacturers must measure equipment, as well as worker productivity and efficiency, production bottlenecks, and many other variables.

- Inventory – Inventory levels must be managed and balanced based on orders and forecasts, a particularly difficult task for lean/just-in-time manufacturing operations.

- Orders and Shipping – Orders for goods must be closely managed and matched with inventories and production; goods must be efficiently packaged and shipped.

- Customers – Manufacturers must ensure their customers, be they distributors or end buyers are satisfied with the finished products they receive.

KPIs for ManufacturingThat Matter

Like most companies going through a digital transformation, manufacturing companies have been investing in cloud applications because of their:

Like most companies going through a digital transformation, manufacturing companies have been investing in cloud applications because of their:

- low upfront costs,

- faster time to deployment,

- highly efficient and flexible functionality and

- low IT demands.

Given the range and interdependencies of operations, a multifaceted suite that integrates many functions on top of a shared-data foundation is especially valuable. That’s why many organizations have been able to measure and improve their KPIs for manufacturing after adopting NetSuite’s cloud-based ERP solution.

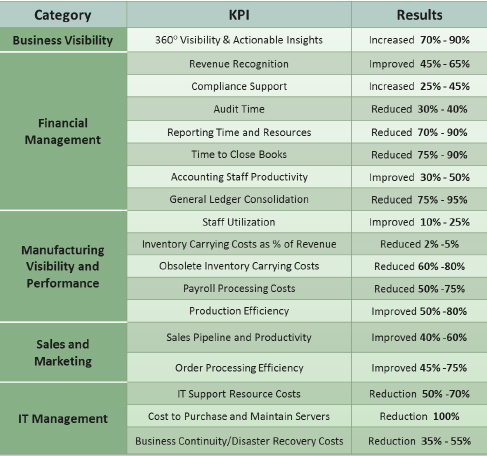

By interviewing and surveying representative Netsuite customers in the manufacturing sector, market research firm SL Associates identified which manufacturing KPIs these companies track, as well as the improvements they’ve realized by basing their core operations on Netsuite’s advanced manufacturing business suite.

Deploying the Netsuite ERP as the foundation for their core business processes generated a range of impressive manufacturing KPI improvements, as illustrated in Figure 1.

Source: SL Associate, 2014 – Cloud-Based Business Solutions Suite Delivers Key Performance Improvement to Manufacturing Companies, August.

Time to Invest in ERP Manufacturing Process Software

The different types of KPIs for manufacturing that are shown in Figure 1 represent just some of the business processes and measurements that can help manufacturers determine how well they’re performing. Many of the improvements shown spring from the breadth and ease of use of NetSuite’s manufacturing process software, and its delivery as a cloud-based service.

Finding an ERPsolution suite sold as a cloud-based service has become a highly desired, and an increasingly required, purchasing consideration. After all, cloud vendors take responsibility for managing, updating and securing the solutions that run in the cloud.

CMP: A Case Study on NetSuite Manufacturing Software

CMP Corp. is a leading HVAC and refrigeration parts manufacturing and distributor, supplying more than 3,000 customers in 95 countries. Based in Oklahoma City, OK, CMP used the Visual manufacturing ERP suite from Infor from 2001 through 2011, but switched to NetSuite’s cloud-based ERP platform in 2012.

“[Infor’s] suite offered the ability to do deep dives into manufacturing KPI data, but only a few CMP employees had the skills necessary to generate useful reports from that data”, explains Adam Harper, CMP’s director of administration. “Even with extensive knowledge of SQL, there were so many tables of data that finding the right fields and data was very time consuming,” he says. “Our two owners spent 30-35 percent of their time pulling data out of the system for themselves and for others.”

By comparison, using the manufacturing metrics dashboard to create customized reports with NetSuite ERP is much simpler, according to Harper.

“NetSuite lets front-line supervisors pull out their own individual data, and they can use their tablets to look at reports.” The shift to NetSuite ERP also helped CMP reduce data “noise” and to focus on the information most critical to its operations.

Among the important manufacturing KPIs for CMP are a variety of financial measures as well as ordering and shipment metrics. NetSuite ERP has helped improve many of these KPIs, Harper says. The company’s monthly financial close, which formerly didn’t occur until about the 20th of each month, can now be done in as little as three to six working days. Likewise, shipping efficiency has “drastically improved,” he says.

However, some of CMP’s most critical KPI measurements are tied to its factory-floor operations. “Our shop is broken into production cells,” Harper explains, “and we track the value-stream income for each cell.” That requires CMP to monitor everything from the “operational equivalency quotient” (how often a machine is actually doing work) to the cost of materials to labor, electricity and various non-operating expenses.

Because they can easily create and update their own reports, CMP’s production cell leaders can more quickly spot and correct potential manufacturing issues. “Before we deployed NetSuite, we weren’t doing a lot of the reports we can do today because it wasn’t practical,” Harper says. “It would have probably taken from a day to a full week to post the type of information an individual cell leader can now pull up in less than 10 minutes.”

Thanks in part to the ability to more tightly manage its production lines, CMP has realized a number of efficiency improvements. Among other benefits, the company’s peak-period backorders have dropped from an average of about $450,000 under a $100,000 average, Harper says.

CMP is still rolling out some of NetSuite’s functionality and expects to use the suite to help improve both its supply chain and inventory operations. Meanwhile, the fact that NetSuite is a cloud-based ERP solution gives CMP confidence that its functionality will always be available. “In 2003, our facility was leveled by a tornado,” Harper says. “So the business continuity that a cloud solution provides is extremely important to us.”

Contact us online to speak with a consultant today.