Executive Summary

A leading private bridal and special occasion dress designer and manufacturer with a national and international presence was struggling to keep its operations efficient through its growth and needed to accommodate a newly remote workforce. As a result of its growth, including both volume and sophistication of operations, the company believed its systems needed a significant upgrade or replacement. They needed a system that would continue to scale and support its growth well into the future. After a comprehensive discovery exercise to better understand and document its internal processes, the company chose Withum to help them implement Oracle NetSuite as its new ERP. The new cloud-based ERP system created several quantitative processing efficiencies benefiting the brand’s operations and supply chain needs.

The Client

The client is a private $50M designer and manufacturer of bridal and special occasion dresses based on the East Coast. Through their private and additional well-known fashion brands, the company offers a wide range of bridal gowns; flower girl, bridesmaid, mother of the bride/groom, social occasion, kids’ party/baby, cocktail, homecoming, prom, pageant, first communion dresses; formal wear/evening wear; and dresses for guests of the wedding. The formalwear company serves customers through many retailers in the United States and internationally.

The Challenge

In addition to their private brand, the company also has other well-known fashion brands. These other brands and international divisions are handled as separate corporate identities within the company’s business model. The company’s operations were primarily dependent on a single enterprise software Apparel Business Systems (residing on an AS400), to facilitate the company’s operations, including aspects of production, accounting, sales, customer service, fulfillment and reporting, and other considerations. The company has utilized this software, including various versions and customizations since 1991. Over time, the organization figured out how to get their jobs done while growing and maintaining some profitability. Unfortunately, this creativity led to:

- unintentional complexities and inefficiencies;

- data risks;

- employee frustration and turnover;

- higher compliance costs with auditors, tax preparers, bankers, insurance providers and other third parties;

- increased cyber security threats; and

- a helpless feeling caused by the pandemic when it came to working remotely and staying connected.

The company used email to complete automation/workflow approvals. Imagine the time it took to investigate who did what and when for any reasonable request. Time spent analyzing past results left little to no time or attention to collaborate with internal and external stakeholders. As a result, the supply chain and related international supplier design lead time took way too long. The legacy customer portal was disconnected from the ERP system and needed to get modernized.

The Approach And Solution

The company needed a system that would continue to scale and support its growth well into the future. They performed a comprehensive discovery exercise to better understand and document its internal processes as a first step.

Through this process, the company understood that their new ERP Software must facilitate job and operational functions of all private company staff and departments. These functions include:

- Production

- Product Catalog & Inventory Tracking

- Accounting

- Sales

- Customer Services

- Warehouse & Fulfillment

- Reporting

They identified the following key considerations that needed to be addressed:

- The company had multiple business entities made up of brands and regional markets.

- The new platform must manage the enterprise and business divisions frictionless.

- The platform can be hosted on-site, off-premises or be a cloud-based solution.

- The platform must be highly scalable and easily adaptable to a growing enterprise without additional dedicated personnel to support the system.

- The platform must have a well-documented API and integrate with third-party applications such as Product Information Management (PIM), eCommerce platforms, and customer support systems.

The Results, ROI

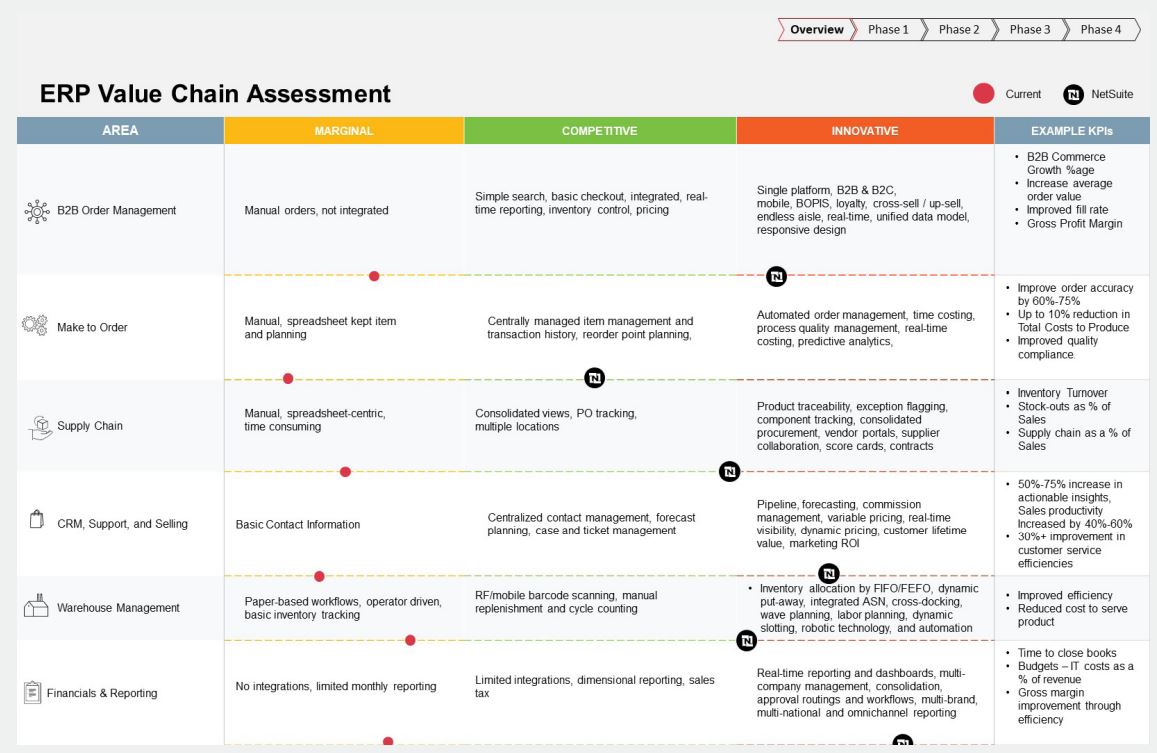

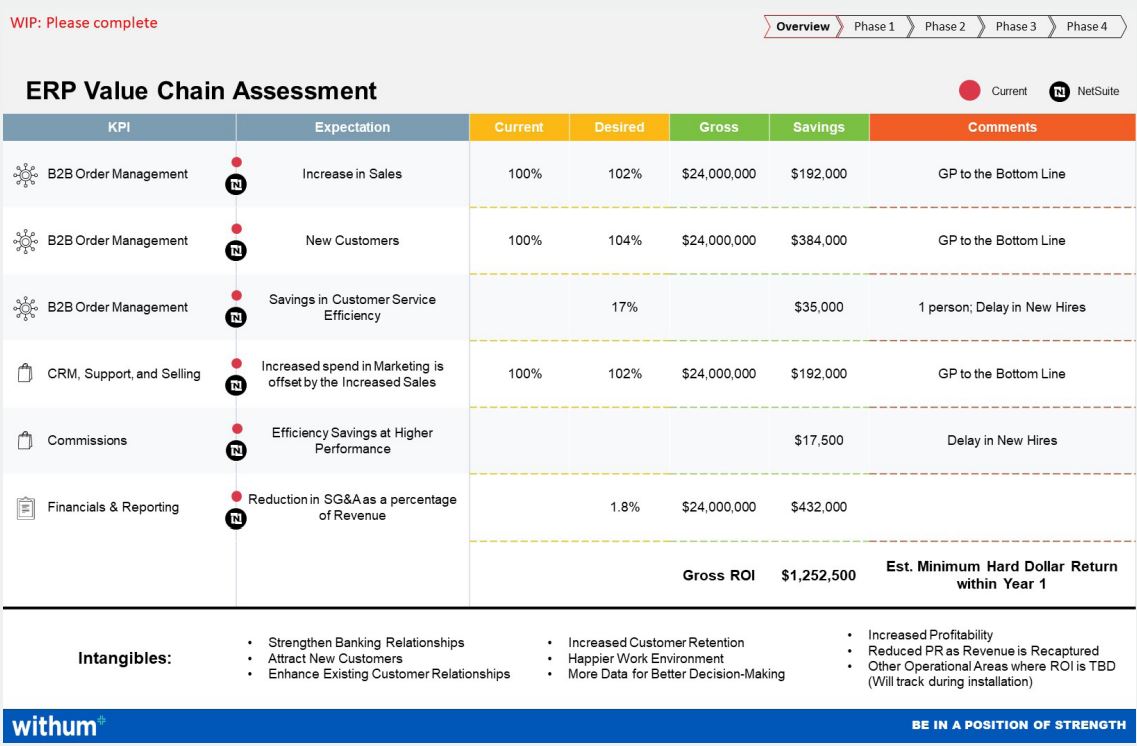

When implementing Oracle NetSuite ERP, Withum leverages partner tools such as the ERP Value Chain Assessment. During this implementation, the Withum team assessed and identified operating environment stages and then moved specific processes from Marginal to Innovative and/or Competitive to Innovative. This project yielded many quantitative processing efficiencies to support “Doing More with Less” and qualitative outcomes with significant intangible value. For example, employees having secure access to data without contacting anyone who maintains off-system worksheets is a great benefit of the newly implemented ERP – saving time and unnecessary steps. Data transparency and reliability are paramount to the workforce in meeting operational goals. Moving data analysis from off system to a common platform for anyone to utilize from anywhere in the world is a significant competitive advantage. What may seem like small wins, these efficiencies matter greatly for companies who modernize after using outdated, on-premises systems for the last 28 years (like in this example).

ERP VALUE CHAIN

Learn how the client’s journey continued by leveraging NetSuite’s SuiteCommerce Advanced (SCA) for improved e-commerce capabilities.

Contact Us

Contact our experts to discuss and address any ERP challenges.

Frost & Sullivan 2024 Global Company of the Year Award

Oracle NetSuite has been awarded Frost & Sullivan’s 2024 Global Company of the Year Award for Leading Innovation in Cloud Business Management Solutions. This recognition underscores NetSuite's unmatched technology and its pioneering role in the cloud ERP industry.